Experience Excellence in Machining with Babin Machine Sales

We are a tool room lathe manufacturer dedicated to delivering exceptional quality and service to our clients. Our Hardinge HLV-H clone lathes not just compliment our Hardinge rebuilding business, they became a replacement for many of our repeat and new customers. The need for high precision metal working lathes is higher then ever before in machine shops, fast prototyping environments, research and development labs around the country. Our competitive pricing combined with the unmatched qualification process guarantees a machine which you won't find at any other dealer and which your machinists will love and appreciate for many years to come.

Every machine gets delivered to you from our Pennsylvania facility where we perform our extensive qualification process. This is unique in the industry, we utilize our 60+ years of Hardinge rebuilding experience and it involves checking, adjusting, fitting, hand scraping and aligning every part of the machine. That's what makes our lathes a Babin lathe.

A Babin lathe is synonymous with great feel, quality, longevity and high precision, like a Hardinge.

Our TML-5Cem, TML-5Cst and TML-5Cnc lineup

TML- 5Cem & TML-5Cst Features and Specifications

TML-5Cem

Ideal for parts requiring high precision

Quick change inch/metric gearbox with 36 changes

- Easy to read digital display on actual spindle rpm

- Infinitely electronic variable spindle speeds from 0 ~ 3500 rpm

- Spindle runout within 50 millionths

- Dual range inch/metric quick change gearbox or Digital Servo Threading with touch screen

- Electric variable feed control on carriage and cross slide

- Hardened and ground spindle mounted on high precision preloaded angular contact ball bearings

- Hardened and ground alloy tool steel bedways

- Turcite-B slideway bearing surface between carriage and bed

- Automatic thread length control with fine adjustable stops to provide accurate threading

- Quick-action tool post slide for threading

- 5C lever type collet closer standard

- 5 HP frequency-controlled motor

- Yaskawa Inverter Drives

- One piece alloy steel material, hardened and ground dovetail

- Hardened and ground leadscrews

TML-5Cst

Threading is a breeze with this.

Additional features of the TML-5Cst:

- fully digital servo driven threading is not limited by mechanical gearbox

- range of English threads from 4 TPI - 250TPI

- range of metric threads from 0.10mm - 6.50mm pitch

- create odd and part specific threading by entering double digits after the decimal point

- single, double, triple and quad lead start with automatic switch between them

- right hand and left hand threading

- touch screen setup

- fast retract speed controlled via touch screen

For Operating instructions click here.

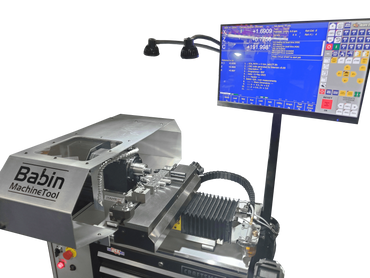

TML-5Cnc Features and Specs

- made with Yaskawa Brushless AC servos

- 5 HP, 3000 RPM EVS spindle drive with electronic dynamic braking

- USA made CENTROID CNC system, see all features in this Brochure or scroll down

- Dual electronic/manual carriage and cross slide hand wheels and Manual snap-up clutch levers for feeds

- Standard and fine hand wheel resolution

- Spindle encoder for threading operations

- 15” color LED with graphics and DRO display

- Solid state hard drive, USB and Ethernet ports

- Shop floor type programming that is easy to use

- G-codes accepted from off-line CAM programming

- Programmable spindle speeds with CCS

- Automatic lubrication system to ways & screws

- Spindle encoder for threading operations

- 5C collet closer with lever operation

- Programmable flood coolant pump

- Homing switches and software limit travel stops

- Feed rate and spindle speed overrides

- Spindle start-stop lever for manual operation

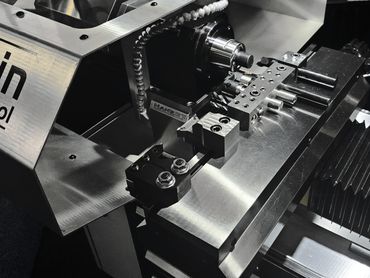

- Precision engineered components and brackets

- Coolant and curved chip guard w/ “swing away” design

- 230 volt, 60 cycle, 3-phase operation, 460V opt.

- Stainless guarding and protection for ball screws

- Full manual operation with DRO position display

- .0001” resolution display

- Interactive conversational programming (Intercon) Icon help features with fill in the blank inputs

- Full color real-time graphics on 15” LED display

- Distance to go display

- Canned cycles for: turning, threading, boring, profile, grooving, cut-off, drilling, roughing and finish cuts

- Digital servo drives and high torque servo motors

- Modular type components

- 11” swing x 16” between centers

- 7” cross slide travel

- #2 Morse taper tailstock

- Precision ground ball screw assemblies

- 5C spindle tooling

- Tapered spindle nose style

- Turcite lined carriage and gib surfaces

- 0001” resolution programming inputs

- Auto lubrication pump w/low level alarm

- Limit switches for homing sequence

nanoGT Photo Gallery

-f56d4d6.png/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:370,cg:true)

Instagram

Babin Machine Sales

Babin Machine uses cookies.

We at Babin Machine use cookies to track clicks on the Contact Us forms. By accepting our use of cookies, your data will be aggregated with all other user data. We think you should know this.